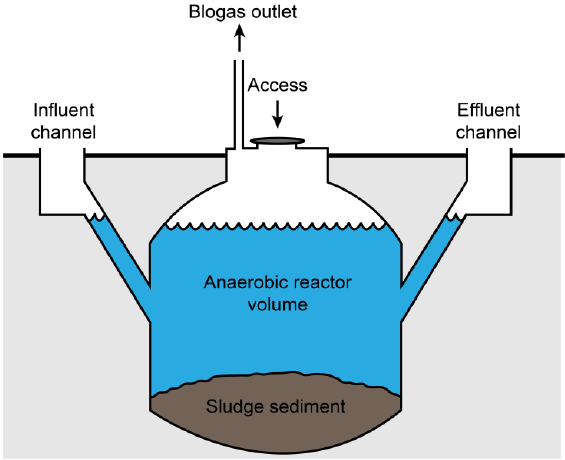

Biogas plants usually consist of at least one digester, which uses organic materials like dung, manure or different plant remains and ferments them in its lower part. In addition, it contains a giant mechanical stirrer to keep the fermentation moving. In the upper part the building is formed cone like, so the escaping gases can be detained. Then the bio-gas-mixture can be released from the gas storage und is available for further usage. The fermentation residues can be pumped out and be used as an organic fertilizer.

Biogas plants convert organic substances into a gas mixture. Inside the digesters (fermenters) a controlled fermentation procedure is performed. The resulting gas consists of circa 60% methane gas and is either directly fed into the gas grid or stored and later used inside of (for example) a cogeneration unit to generate electric energy.

The remaining fermentation residues will be left behind by the methane bacteria in the metabolization process and then can be used as an organic fertilizer.

The procedure usually consists of 4 smaller stages, which cannot really be split up and so will be executed simultaneously.

The Procedure:

Hydrolysis:

The source materials (fats, carbohydrates and proteins) will be disaggregated by enzymes like amylases, proteases and lipases into their chemical components (such as fat acids, simple/multiple sugars and amino acids).

Acidogenesis:

By metabolization of the dissolved compounds by acidifying microorganism new organic acids occur.

Acetogenesis:

Those acids now will be broken down into Carbon, hydrogen and acetic acid, the “prerequisites” of biogas.

Methanogenesis:

The last step is anaerobic – without any air. Methane bacteria convert at first acetic acid into carbon dioxide, hydrogen and methane, then carbon dioxide and hydrogen into water and methane. In the end the resulting gas will be desulphurised, cleaned and purified.

Local Usage:

In Germany and in the Ore Mountains (Erzgebirge) biogas plants usually are used by farmers. That way they are able to immediately convert their organic waste into electric current and organic fertilizer. One single cow is able to produce about 35 m3 manure or in other words: a maximum of 700m3 biogas in one year. Besides that, there is also a biogas plant we have visited only a few kilometres away from “Marienberg” in “Hilmersdorf”. It is operated by the “Bauernland Agrar AG”.

In Germany and in the Ore Mountains (Erzgebirge) biogas plants usually are used by farmers. That way they are able to immediately convert their organic waste into electric current and organic fertilizer. One single cow is able to produce about 35 m3 manure or in other words: a maximum of 700m3 biogas in one year. Besides that, there is also a biogas plant we have visited only a few kilometres away from “Marienberg” in “Hilmersdorf”. It is operated by the “Bauernland Agrar AG”.

image sources:

Entry Image

Schematic Plant

Biogas Plant

Be First to Comment